Construction instructions for hatching bolts in construction installation

Expansion bolts are also known as expansion plugs, expansion bolts are specially designed bolts with very good bearing capacity and load capacity. Expansion bolts have an expander called a hatch to increase strengthen the connection ability between structures or between the frame structure and the concrete wall of the building.

What are expansion bolts (expansion plugs)?

To attach a heavy object to a concrete wall, a special bolt with a very high bearing capacity must be designed, from which expansion bolts are manufactured. Expansion bolts are also known as expansion plugs, expansion bolts are specially designed bolts with very good bearing capacity and load capacity. Expansion bolts have an expansion part called an expansion shirt to increase strengthen the connection ability between structures or between the frame structure and the concrete wall of the building.

Construction and materials of hatch bolts

Expansion bolts have a round shape, the outer bolt body has an expansion part called an expansion shirt, expansion bolts are very diverse in size, designed and manufactured to suit each purpose and use, each 1 set of expansion bolts includes 01 bolt, 01 hatches, 1 flat black bolt, 1 warped black bolt and has 1-2 nuts, depending on working conditions and load.

Expansion bolts and plugs are manufactured from materials such as carbon steel with strength 4.6, galvanized by electrolytic zinc or hot-dip galvanized, colour plated. If the joint requires high aesthetics, great corrosion resistance, the expansion bolts are manufactured using stainless steel materials such as INOX 201, INOX 304, INOX 316.

Applications of Bolts hatch

The application of expansion bolts, pipe expansion plugs is the connection between cypher plates, supports, steel structures with concrete structures, support systems or space steel truss structures with concrete walls and works…

Construction Bolts bloom

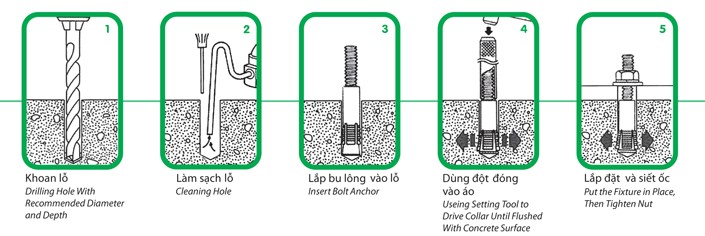

Construction steps of expansion bolts – expansion switches

- Step 1: Drill a hole by the design in terms of depth and hole diameter, hole diameter is the most important parameter when drilling holes, so pay special attention to the diameter when drilling holes. suitable diameter. As for the depth of the hole, it’s okay to drill a little too much.

- Step 2: Clean the drill hole with specialized tools.

- Step 3: Insert the nail and hole expansion switch and adjust the nut to match the given design.

- Step 4: Nail and fix bolts, will make sure the connection.

- Step 5: Check and adjust the bolts to your liking.

WDB is the leading brand in providing civil materials today. Contact us now to discover more WDB products for your project!