Chemical bolts – Chemicals for transplanting bolts

Chemical bolts (BLHC) are quite special bolts with many different names such as chemical anchor bolts, chemical expansion bolts, or chemical stoppers… The special feature of this bolt is that is the use of chemicals (usually called steel glue) to bond bolts (threaded rods) to concrete, stone, or brick foundations.

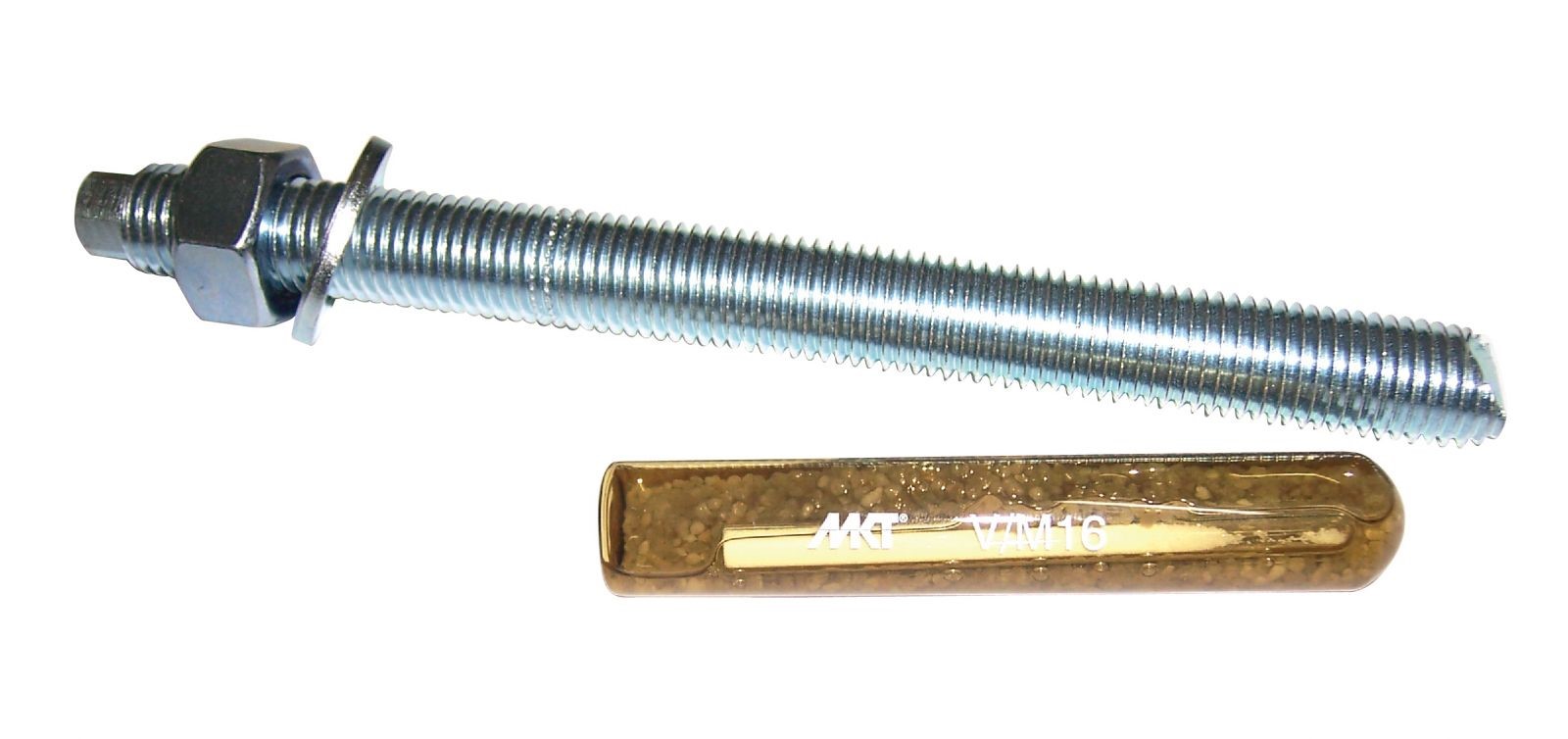

The chemical bolt is composed of 2 parts:

- The bolt part (threaded rod): The threaded part, has two ends, one end is used to drill deep into the drill hole, usually with a V-shaped bevel to prevent the threaded rod from being rotated during use. One end is tapered so that a hammer can be used to drive the threaded rod into the hole. Threaded rod body has a thread throughout, normally there will be 2 parts, a part that goes deep into the hole and a part that protrudes outside, these two parts are marked separately. The part Ecu + Black Dragon is responsible for tightening the structure.

- The chemical part (steel implant): An indispensable part in construction to help create the connection between the threaded rod and the substrate surface.

Applications of chemical bolts

Chemical bolts have many functions, so they are widely used. Currently, many projects are using chemical bolt products. As follows:

- Used to make racks to store heavy goods to create safety for customers and users

- Used in strong steel anchors for railings

- Used for works on installation of canopy roofs and roofs on terraces or roofs

- Construction and installation of emergency stairs of high-rise buildings

- In addition, the product is also used in the construction of anchors for industrial buildings

- Install a stronger steel pole base when the steel posts are damaged or misplaced

- Chemical threaded rods for installing rubber gaskets with expansion joints and exhaust fans are fine.

- Constructions specializing in roads, bridges and basements are used the most. Because bolts have the feature of bearing heavy loads and withstand strong vibrations

Classification and advantages and disadvantages Chemical bolts

Chemical bolts (BLHC) have 2 product lines:

- Tubes (glass tubes or nylon tubes)

- Large tube packaging

Advantages and disadvantages of chemical bolts between tubes and tubes:

In terms of bond strength: At this point, tube-type BLHC has a higher bond strength, due to its chemical properties. The chemical composition of the BLHC tube with the formula is 1 pure epoxy (pure epoxy) which is the highest strength epoxy in the product systems from polymer science. Meanwhile, tubular BLHC is usually supplied from Epoxy Acrylic or Methyl Methacrylate base, so the adhesion strength is lower than BLHC tube (pure epoxy) from (20:30) per cent.

- About construction time: The hardening time of tubular BLHC ranges from 2-10 minutes, depending on the ambient temperature, while the hardening time of tubular BLHC is about 1:3 hours. The tubular BLHC allows for a faster installation time of the structure, however, during winter construction, the hardening time is very fast, requiring the installation stage to be precise, without interruption because it is difficult to correct and align later. when the Bolts are installed.

- About usability and preservation

+ Both tube and tube types require specialized equipment for installation. For tubular BLHC: hand drill, with hexagon head (provided by the distributor). For BLHC in the tube, Glue Gun is required (supplied by the manufacturer).

+ Due to being packed in glass (or PVC) tubes for each tube, the loading and storage of BLHC tubes are a bit difficult, easy to cause breakage, damage, impact…, buyers should pay attention to this problem to avoid waste. The BLHC is in tube form because it is packaged in a glue tube, hard plastic, so it is easier to load and store.

- About adaptability

+ One thing to note is that the use of BLHC in the form of a tube, the drilled hole must ensure the correct size proposed, with a small error, in the case of drilling the hole is wide and narrow (due to drilling with steel, skewer, oblique …), too deep, too shallow, not allowed to use tubular BLHC (in many cases it is impossible to install). Since the BLHC tube has been dosed for 1 bore (standard size). When encountering the above cases, using BLHC in tube form will solve the problem, because it is possible to customize the width and obliqueness of the drill hole by compensating but the gap is behind schedule, the connection is guaranteed.

+ Construction against the ceiling, reverse pump, using tubular BLHC is easier (due to fast setting) than using tube BLHC.

Why buy chemical bolts at wdb.com.vn?

Come to wdb.com.vn to experience great products and services. We provide chemical bolts, reliable civil materials, bringing quality and economic efficiency to your construction. Besides, WDB has many years of operation in the field of construction. and provide civil materials – additives – construction chemicals at many large and small construction projects across the country.

We are always committed to providing consumers with superior quality products and services. Contact us to get a unique design and suitable for your home architecture!

WDB is the leading brand in providing civil materials today. Contact us now to discover more WDB products for your project!